DIOnavi. proven to have superior accuracy and convenience

DIOnavi. proven to have superior accuracy and convenience

The accuracy of the implant placement is determined at the first drilling with a surgical guide. Because after the first drilling, the second drill goes in the direction of the initial hole with double contacts on the surgical guide and bone, so, many experts believe that the hole generated by the first drilling plays a decisive role in guiding the correct path in implant accuracy.

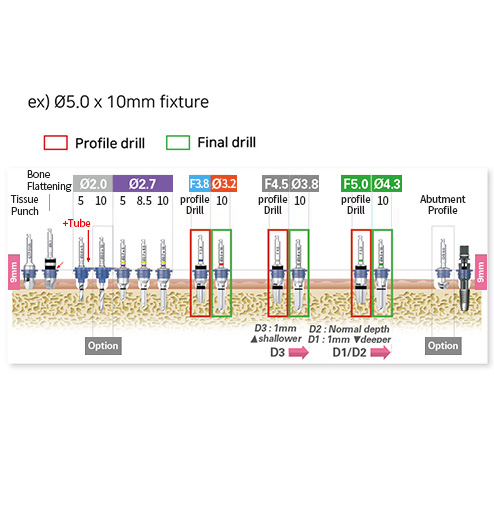

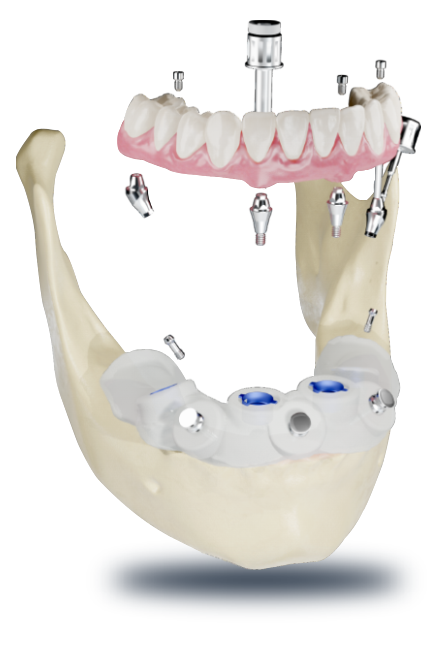

So, DIOnavi. focused everything on the accuracy of the first drill. Particularly noteworthy part is the differentiated drill tube that guarantees its precision. The drill tube of the DIOnavi. maximizes the contact area with the drill to hold the shaking or to prevent horizontal movement during drilling. The longer drill tube maximizes the contact area closely that prevents the shakiness and movement. Additional 9㎜ tube and 12㎜ tube optimized for the anterior tooth launched sequentially after the 7㎜ drill tube that is mounted on master surgical kit. DIO has evolved into the current DIOnavi. system, which can be conveniently treated regardless of the amount of mouth opening, while increasing the accuracy of the procedure.

Along with the length of DIOnavi., the drill tube of DIOnavi. is designed to be inserted into the punched soft tissue, focusing on the convenience of limited mouth opening with the best precision.

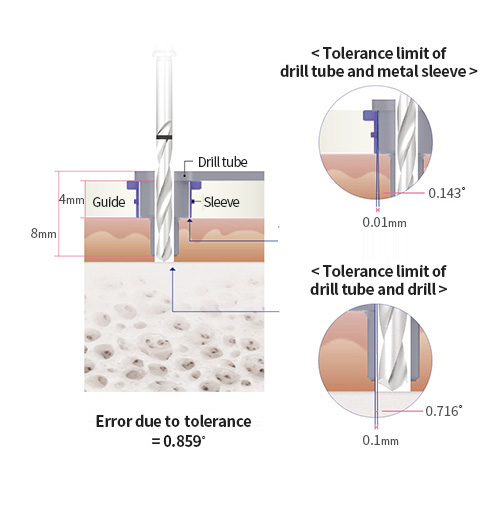

It is differentiated in all aspects of accuracy and convenience. In addition, all precision processing technology in Korea has been concentrated to eliminate errors in drill tubes.

The tolerance between the drill tube and guide is 0.01mm, which is the minimum tolerance value that can be narrowed down with Korea processing technology.

The result of the study that the tolerance of 0.01mm between the drill tube and the guide arithmetically shows an error range of less than 1 degree (DIOnavi. average error is 0.4 degree),

while presented a 5-degree error when drilling without using a drill tube in other study results.

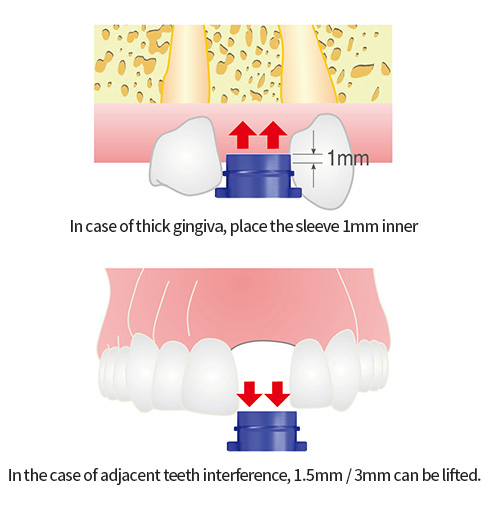

To improve the accuracy of the DIOnavi., the patient-customized offset system was also a very crucial part. The DIOnavi. drill is a straight shape that can be applied to the offset system, allowing the guide height to be flexibly adjusted even in the interference of a thick gingiva or an adjacent tooth. A typical case uses the default offset value of 9㎜, 10.5㎜, and 12㎜, narrow cases are 12㎜ for the default offset value, and the wide case has a default offset value of 8㎜, making the procedure smoother and more precise.